The choice in stock

The most cost effective way to produce my booklet design at a mass scale I found would be to print the design on mid-sheen card at 160-180gm.

The main reason for this is the binding technique.

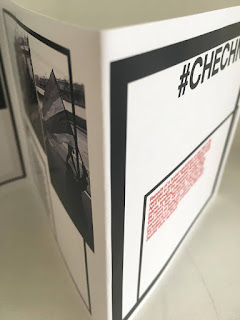

As I have planned to fold these designs as booklets, the thickness of the card is very important. Using 160gsm keeps the folds of the card from breaking or cracking easily over time, keeping the design looks professional. Another reason for the choice in stock is durability. As my booklet design is created to be small and convenient, it is more prone to damage and saturation, Using this chosen thickness of stock provides some protection again scratching and bending.

The third reason for my choice in stock is to display a more professional look. A slight sheen to the paper works wonders for images and color in and out of the booklet design. Reflecting light from these elements creates a more professional and premium look.

The choice in binding

My choice in folding the booklet design is the key to keeping mass production, cost and time effective. Folding requires no extra material and it keeps singular production of the design much more time effective. This also means that there is less. chance of there being any mistakes when it comes to the binding method of the booklets.

Simple cover choice

I have decided to not choose a different design method for the front and back cover of the leaflet. The main reasons for this are that it keeps the mass production of the booklet design cost effective. Secondly, it would be difficult to combine a second type of stock towards a booklet which has been designed to be folded back onto it'self as the binding method would suggest.

No comments:

Post a Comment